Hongrui Metal is a professional metal cold forming parts factory.

The company is located at No. 7 Qingdao East Road, Taicang Economic and Technological Development Zone. It is adjacent to Shanghai to the south, just over 50 kilometers away from Hongqiao Airport. To the west, it connects with Suzhou, and to the north, it is close to Changshu. The location boasts a superior environment and extremely convenient transportation.

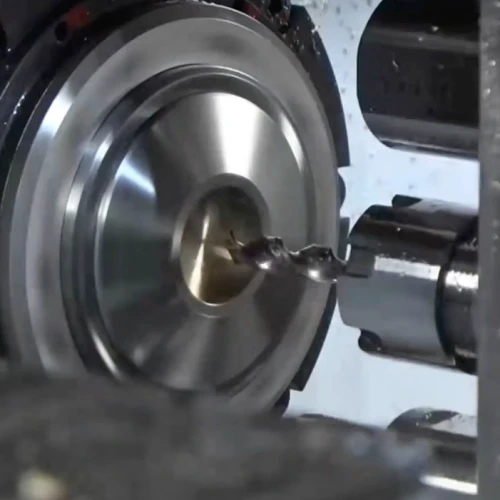

Equipped with state-of-the-art imported production machinery, our company is supported by a cadre of seasoned technicians, each with a wealth of experience in the metal cold forming sector. We pride ourselves on a diverse product portfolio, marked by superior quality and competitive pricing. Our dynamic R&D team, coupled with cutting-edge testing facilities, positions us at the forefront of product innovation and design.

Our products are integral to a broad spectrum of industries, including electronics, telecommunications, electrical appliances, communications, computing, medical equipment, maritime, furniture, and anti-corrosion solutions. We source our materials from premium grades such as SUS410, SUS304, SUS316, and Baosteel 302HQ stainless steel wire, ensuring the highest standards of quality and performance.

Due to these advantages, cold forming can be considered as an alternative to hot forging, casting, powdered metal, machining, welding and stamping or reinforced plastics/composites.

With in-depth technical knowledge, complete mould design and metal forming capabilities, we are able to manufacture precision cold formed parts of great complexity.

Co-design with customers to produce powerful and diverse metal parts by integrating core technologies, advising customers and tailoring part production solutions.

Cold forming technology not only makes it possible to forge parts that meet more than 90 per cent of requirements without any loss of material, it also reduces or eliminates the need for secondary operations.

By elevating our management standards, we are able to present customers with exceptionally competitive pricing, thereby partnering with them to venture into new market frontiers.

Equipped with state-of-the-art 2-6 die multi-station cold heading machines, 4-5 axis machining centers, and high-efficiency Swiss-type lathes, we ensure the precision and perfection of every component. Our rigorous quality management system, bolstered by advanced film thickness gauges, spectrometers, and metallographic microscopes, subjects every process to stringent quality control, guaranteeing that our products adhere to the highest standards. Boasting multiple invention patents, our team's dedication to innovation and excellence is unwavering.

Step into our factory, and witness the fusion of cutting-edge manufacturing technology and rigorous quality control, culminating in the delivery of unparalleled products and services to our esteemed customers. Click the button below to uncover the full extent of our manufacturing prowess and explore how we can elevate your business to new heights of excellence.

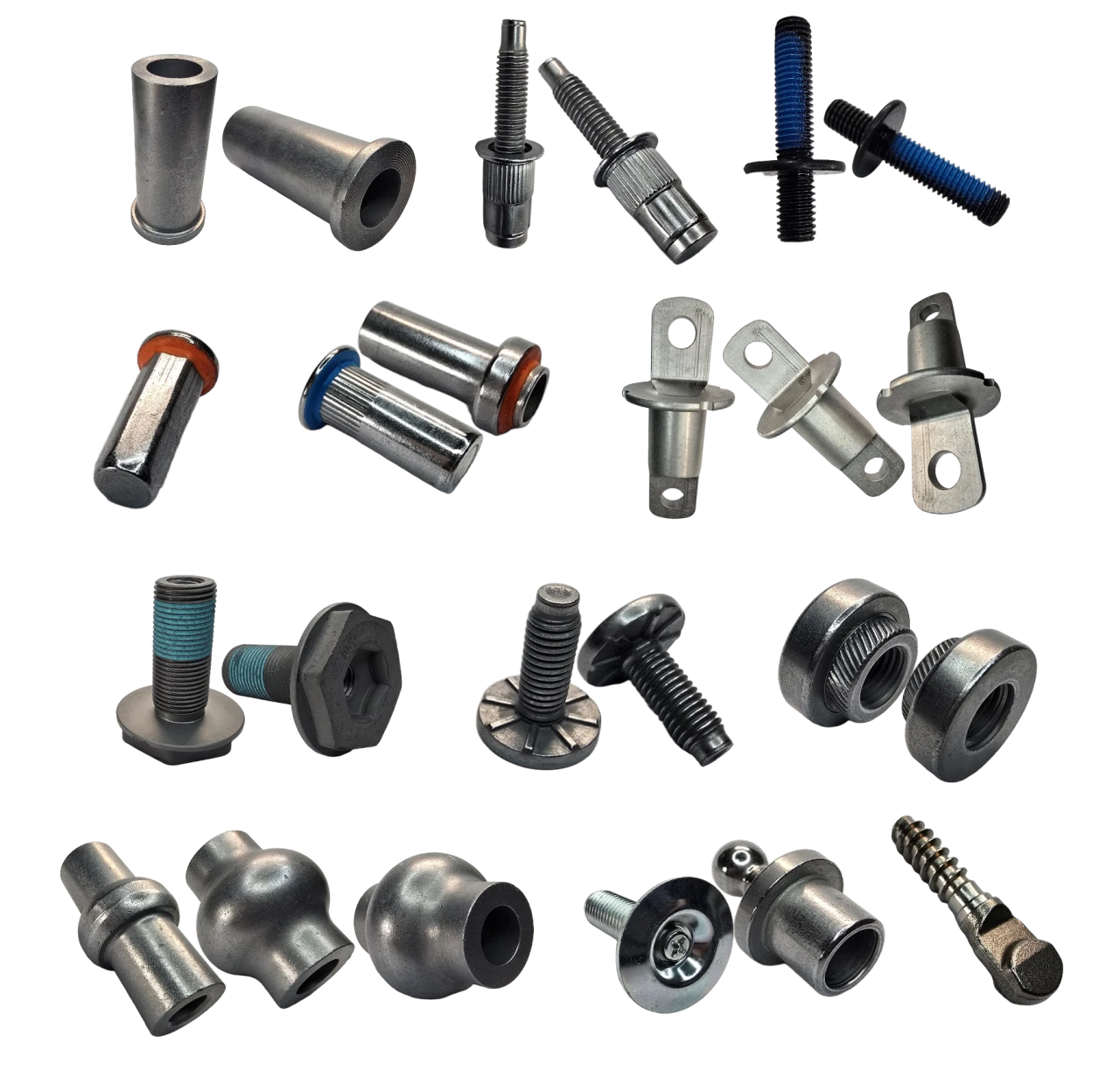

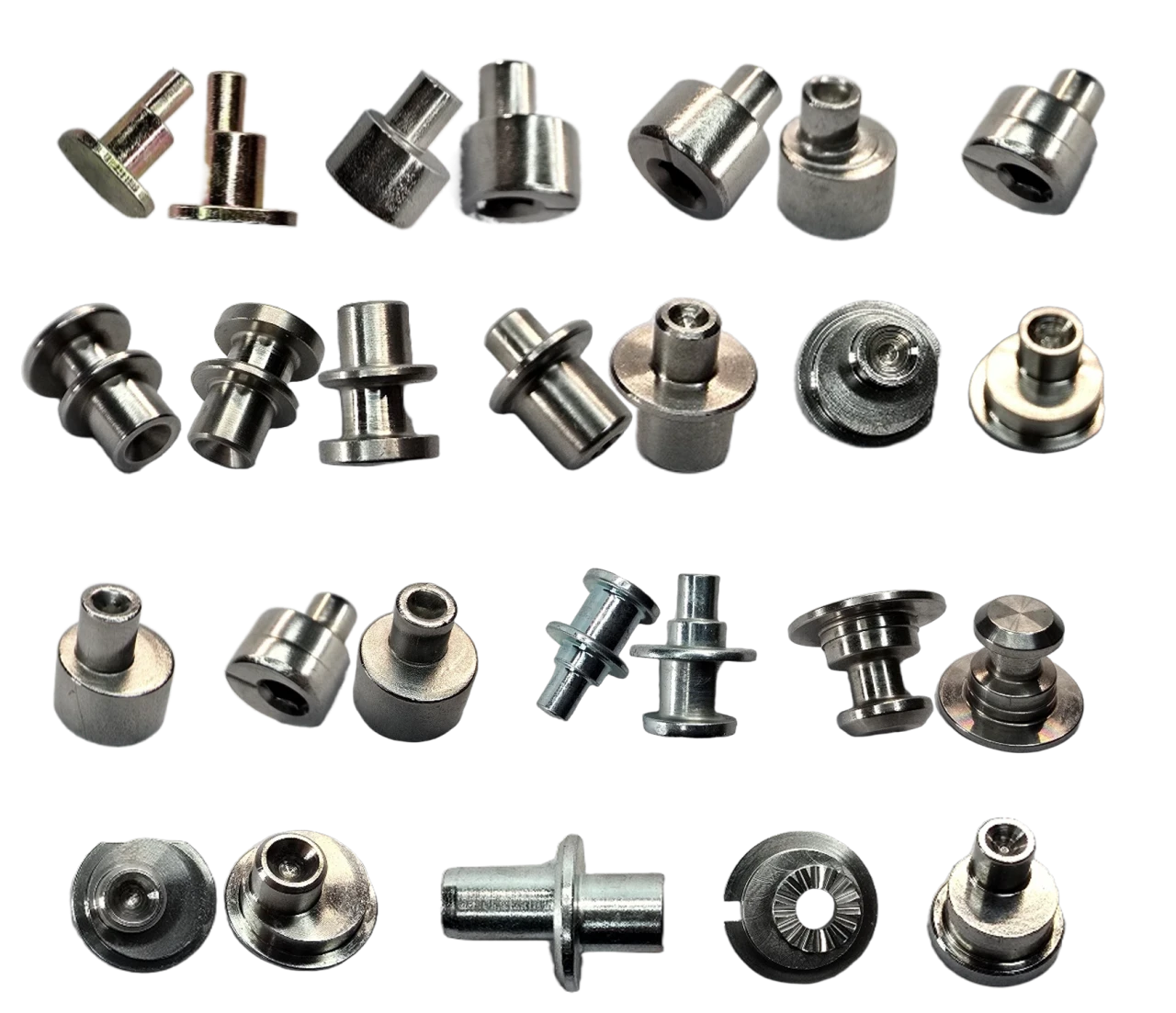

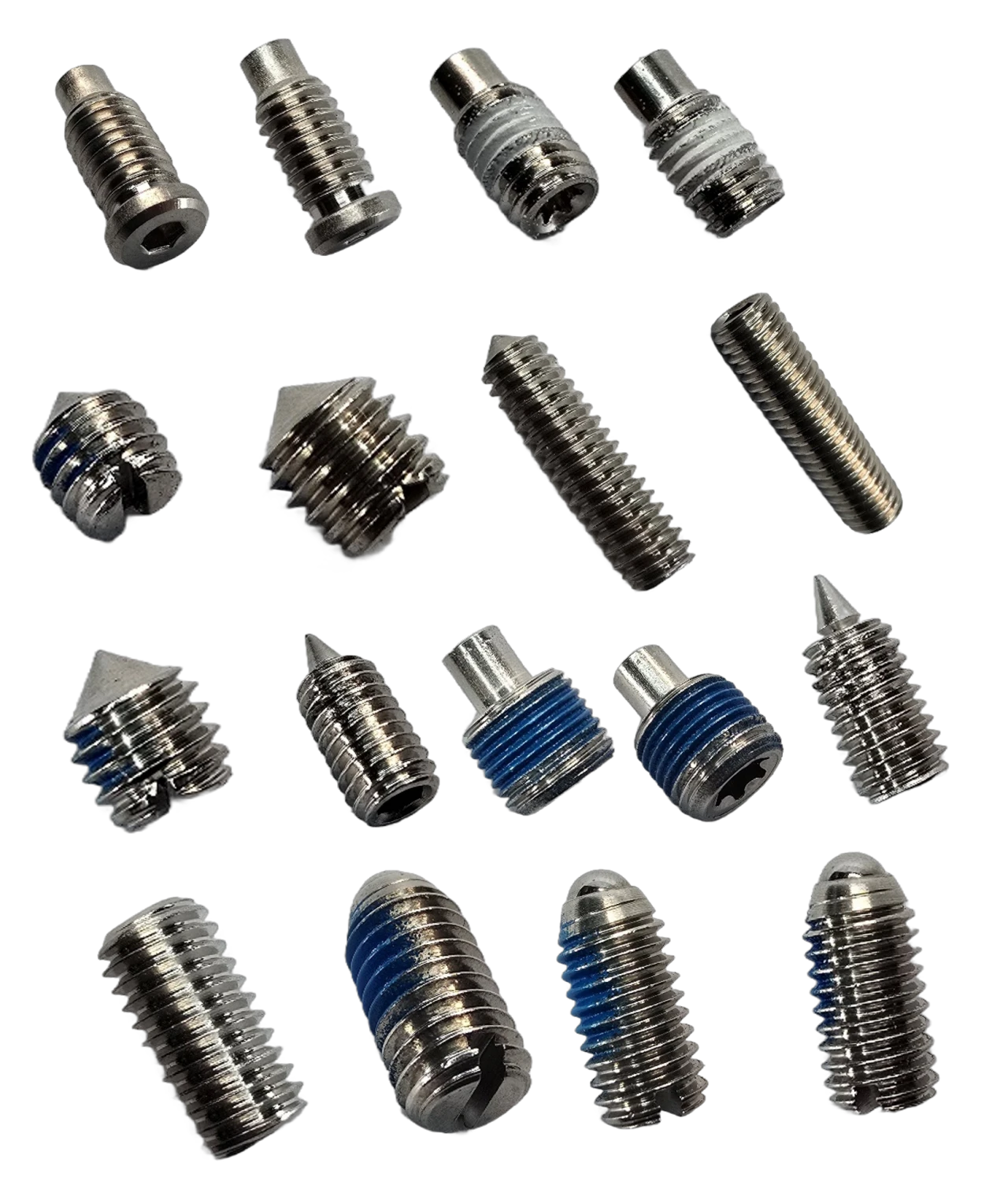

Delve into our extensive array of products, spanning from multi-station cold heading stainless steel stepped rivets to intricate transmission components, as we present a full spectrum of precision manufacturing solutions. From eccentric rivets and automotive components to miniature screws, titanium alloy parts, and stainless steel set screws, each of our machined and Swiss-type lathe parts is meticulously engineered and crafted, ensuring adherence to the most exacting industrial standards.

Our state-of-the-art factory leverages cutting-edge technology and rigorous quality control protocols to guarantee that every product embodies superior performance and robust durability. Click the button below to explore our comprehensive product series and uncover how we craft tailored precision part solutions to propel your business forward.

Address: No.7 Qingdao East Road, Taicang Economic Development Zone, Suzhou, Jiangsu, China

Email: [email protected]

Phone: +86 (0) 512-53441399